Fabricating roller shades is both an art and a science. While experience plays a big role, even seasoned professionals can run into costly errors—especially when processes are rushed or materials aren't properly handled.

At Sunlo Corp, we work closely with shade makers every day, and we've seen the same issues pop up time and again. Here are three common mistakes fabricators make—and how to avoid them to keep your projects running smoothly.

1. Incorrect Measurements or Deductions

The mistake: Cutting fabric to incorrect dimensions, especially when factoring for inside or outside mounts.

Even a half-inch error can ruin a finished product. Misunderstanding deduction rules—especially with blackout fabrics or tight-fitting installations—can lead to wasted materials, remakes, and frustrated clients.

How to avoid it:

-

Use clear, standardized measurement forms

-

Double-check deductions by mount type and hardware

-

Label orders clearly with mount type, control side, and deductions applied

Pro Tip: If you're switching between brands of hardware or tubes, always re-confirm deduction values.

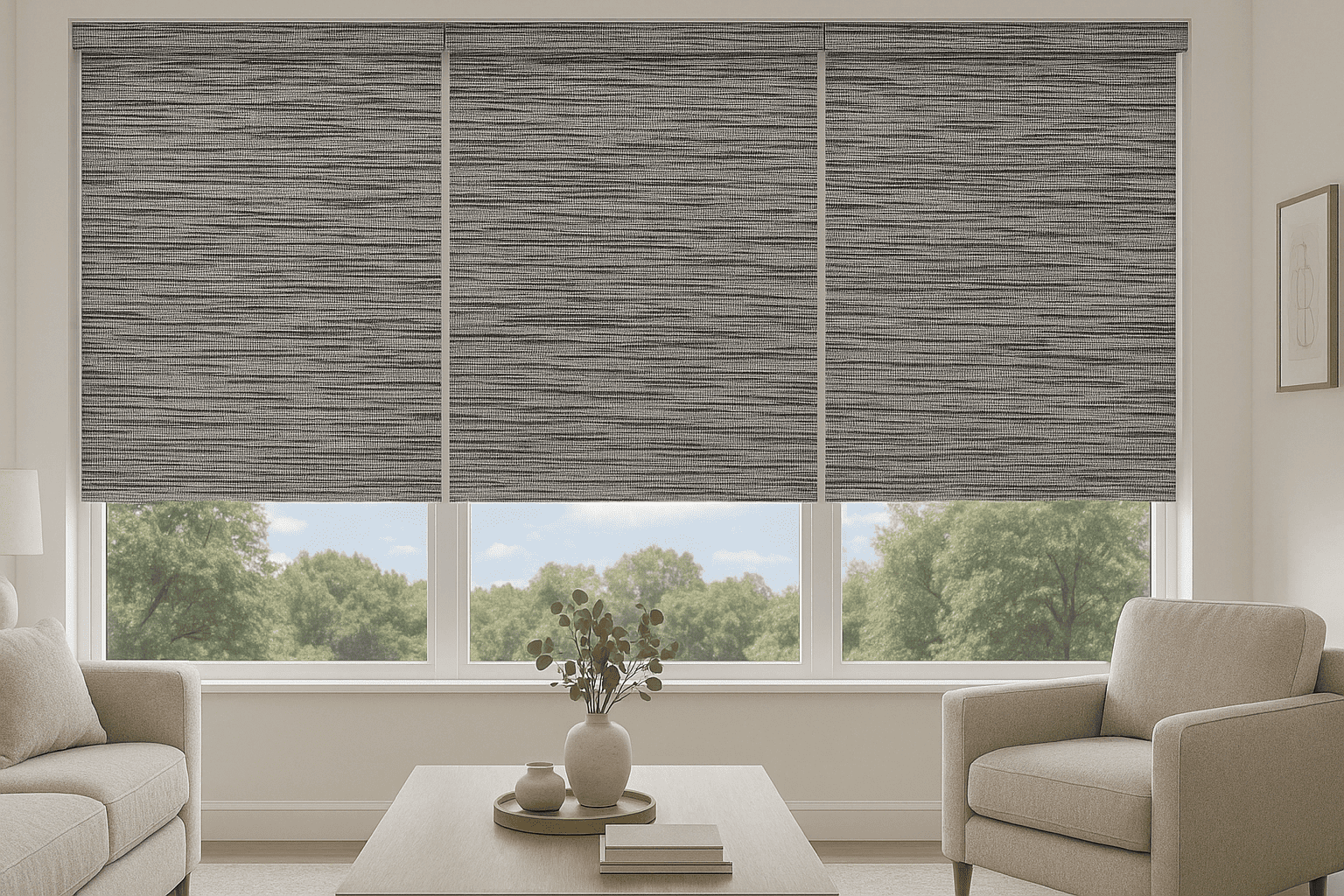

2. Using the Wrong Fabric for the Room

The mistake: Installing a fabric type that doesn't suit the room’s lighting, privacy, or temperature needs.

For example, placing light-filtering fabric in a nursery that needs darkness, or using blackout in a room where natural light is preferred, can lead to unsatisfied customers—even if the installation is perfect.

How to avoid it:

-

Ask the right questions up front: What is the room used for? When is it most active?

-

Keep a physical swatch book to help clients visualize each fabric type

-

Educate clients on the differences between sunscreen, blackout, and light-filtering fabrics

Pro Tip: Light-filtering fabrics with warmer tones can help soften direct sun while still keeping a bright atmosphere.

3. Poor Fabric Handling and Storage

The mistake: Damaging fabric rolls through improper handling or storing them in humid or dusty environments.

Wrinkled, stretched, or warped fabric leads to tracking issues and imperfect roll-ups. Fabric needs to be stored carefully to maintain its shape and performance.

How to avoid it:

-

Always store rolls horizontally on flat surfaces or racks

-

Keep them sealed in plastic until ready to use

-

Avoid stacking heavy items on top of fabric rolls

-

Maintain a clean, dry workspace

Pro Tip: Use end caps on rolls and handle with gloves when possible to keep oils and dirt off the material.

Final Thoughts

Avoiding these common mistakes doesn’t just protect your fabric—it protects your time, margins, and reputation. With a little extra care in measuring, planning, and handling, you can save on material waste and deliver a better product every time.

At Sunlo Corp, we supply premium roller shade fabrics built for professionals who take pride in their work. Need help choosing the right fabric or setting up a more efficient workflow? We're here to help—every step of the way.

Share:

The Benefits of Stocking Locally Sourced Fabric